Grundfos

By using 3D scanning, Grundfos has experienced several benefits and results across the organization.

Zebicon works for many different customers and industries. We respect our customers, and their wish for confidentiality. Below you will find an extract of the companies that we have worked with and sold metrology systems to.

With case stories we let the customers speak and present some of the many measuring tasks, we have solved over time. Here our customers explain the benefits of using optical metrology from Carl Zeiss GOM Metrology, as well as the advantages of cooperating with Zebicon.

You will also find case stories about metrology systems we have sold to Danish companies and what considerations were behind the purchase.

By using 3D scanning, Grundfos has experienced several benefits and results across the organization.

The Memorial stone of Ludvig Mylius Erichsen was 3D scanned to document the stone's condition and the course of the crack, to conclude wether the current protection was enough.

In a development project with Siemens Gamesa, Zebicon has optimized the wind turbine manufacturer’s measurement process of stators and flanges.

C.K. Produktion has increased their customer trust and improved their quality control by using the fully automatic ATOS ScanBox 4105 in combination with the 3D scanner ATOS Q.

Belden Cekan A/S uses CT scanning to document and validate parts in the development department, where they look at geometries, positioning and contact elements.

HBN-Teknik has invested in the fully automatic ATOS ScanBox 5120, for running in new products and part verification.

Vestas Towers A/S wanted to have a 3D coordinate measurement of flanges on a tower section to clarify any loads during assembly.

Multi-Wing International needed knowledge about possible bendings on the tip of the axial fan, as these could give undesirable consequences during operation.

For Vattenfall A/S, Zebicon has measured the distance between bolts on wind turbine platforms in Oresund to ensure that the towers fit exactly on the platforms.

The National Museum of Denmark wanted to analyze whether the stones decay from wind and bad weather. Zebicon used 3D scanning to document the decay of the stones.

Zebicon has CT scanned a Kinder Surprise egg to illustrate how computer tomography can be used to inspection and analysis of hidden elements.

Zebicon has CT scanned different electronic components, which were embedded in other materials. The data was used to document and analyze the components.

MarineShaft has invested in the T-SCAN hawk 2 handheld 3D scanner and the TRITOP coordinate measuring system, which enables precise on-site measurement of complex parts.

Ammeraal Beltech Modular has invested in the fully automated ATOS ScanBox 4105, which is used for quality control of tools and parts.

Sonion A/S needed to measure and analyze a small plastic part to approve the product, as well as document air inclusions and fiber structure.

The plastic company HN Group has invested in the fully automatic ATOS ScanBox 4105, for documentation and quality control.

GN Netcom wanted more knowledge about the interaction between internal elements in an assembled headset, including location and connection between cables, PCB, and speaker.

Vestas industrial cooling wanted to have a fiberglass component 3D scanned in order to do a flow simulation and modify the component in the stage of development.

GN ReSound A/S wanted to analyze the fiber structure in a toggle, which is a button with two positions used as a volume button in a hearing aid.

Zebicon 3D scanned a cylinder head for the speedway rider Kenneth Bjerre, who wanted to create an identical copy to create two identically performing engines.

Lani Pixels A/S got a 3D scanning of a human face, which was used to create a lifelike animation of a face that step by step was transformed into a werewolf head.

Artist Bine Lehmann wanted to 3D scan the sculptures "U Go Grlz" to reproduce and scale the works, as well as investigate the best production method.

Zebicon made a complete surface scan of four wind turbine hubs, which were subsequently compared with the CAD part.

The modern artist Gudrun Steen-Andersen is a figurative sculptress. She wanted to 3D scan her sculpture Satellite to get an exact digital model for an artistic experiment.

Oticon A/S wanted to check the quality of the component 'hook'. Zebicon used CT scanning to make a full-field surface documentation and measure the inner geometries.

In connection with Herlufsholm's 450th anniversary, the school wanted to have a statue of the school's founders to be 3D scanned and recreated in bronze.

LEGO Systems A/S wanted to get more knowledge of machine tooling to be able to enhance their CAM stragegy, tool-life politics, and to optimize the choice of cutting tool.

A student from Aarhus School of Architecture wanted 5000 years old potsherds to be scanned with the purpose of using the Stone Ages design in a modern dinnerware.

A chain of Danish builder merchants wanted to have 3D scanned a roaring doll from their TV commercials, in order to reproduce a mini version to sell in the stores.

The artistic coorporation A Kassen wanted a 3D scanning of a chokolate cookie to make a large scale rosette, which should hang in the art museeum GL. Stand.

Zebicon made a complete surface scan of four wind turbine hubs, which were subsequently compared with the CAD part.

Multi-Wing International needed knowledge about possible bendings on the tip of the axial fan, as these could give undesirable consequences during operation.

The modern artist Gudrun Steen-Andersen is a figurative sculptress. She wanted to 3D scan her sculpture Satellite to get an exact digital model for an artistic experiment.

The National Museum of Denmark wanted to analyze whether the stones decay from wind and bad weather. Zebicon used 3D scanning to document the decay of the stones.

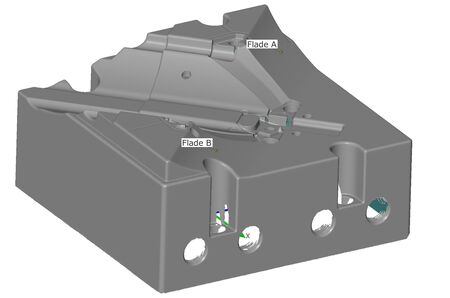

LEGO Systems A/S wanted to get more knowledge of machine tooling to be able to enhance their CAM stragegy, tool-life politics, and to optimize the choice of cutting tool.

Zebicon 3D scanned a cylinder head for the speedway rider Kenneth Bjerre, who wanted to create an identical copy to create two identically performing engines.

Artist Bine Lehmann wanted to 3D scan the sculptures "U Go Grlz" to reproduce and scale the works, as well as investigate the best production method.

In connection with Herlufsholm's 450th anniversary, the school wanted to have a statue of the school's founders to be 3D scanned and recreated in bronze.

A chain of Danish builder merchants wanted to have 3D scanned a roaring doll from their TV commercials, in order to reproduce a mini version to sell in the stores.

The artistic coorporation A Kassen wanted a 3D scanning of a chokolate cookie to make a large scale rosette, which should hang in the art museeum GL. Stand.

Vestas industrial cooling wanted to have a fiberglass component 3D scanned in order to do a flow simulation and modify the component in the stage of development.

A student from Aarhus School of Architecture wanted 5000 years old potsherds to be scanned with the purpose of using the Stone Ages design in a modern dinnerware.

Lani Pixels A/S got a 3D scanning of a human face, which was used to create a lifelike animation of a face that step by step was transformed into a werewolf head.

Belden Cekan A/S uses CT scanning to document and validate parts in the development department, where they look at geometries, positioning and contact elements.

Sonion A/S needed to measure and analyze a small plastic part to approve the product, as well as document air inclusions and fiber structure.

Oticon A/S wanted to check the quality of the component 'hook'. Zebicon used CT scanning to make a full-field surface documentation and measure the inner geometries.

GN Netcom wanted more knowledge about the interaction between internal elements in an assembled headset, including location and connection between cables, PCB, and speaker.

Zebicon has CT scanned different electronic components, which were embedded in other materials. The data was used to document and analyze the components.

GN ReSound A/S wanted to analyze the fiber structure in a toggle, which is a button with two positions used as a volume button in a hearing aid.

Zebicon has CT scanned a Kinder Surprise egg to illustrate how computer tomography can be used to inspection and analysis of hidden elements.

MarineShaft has invested in the T-SCAN hawk 2 handheld 3D scanner and the TRITOP coordinate measuring system, which enables precise on-site measurement of complex parts.

Vestas Towers A/S wanted to have a 3D coordinate measurement of flanges on a tower section to clarify any loads during assembly.

In a development project with Siemens Gamesa, Zebicon has optimized the wind turbine manufacturer’s measurement process of stators and flanges.

For Vattenfall A/S, Zebicon has measured the distance between bolts on wind turbine platforms in Oresund to ensure that the towers fit exactly on the platforms.

MarineShaft has invested in the T-SCAN hawk 2 handheld 3D scanner and the TRITOP coordinate measuring system, which enables precise on-site measurement of complex parts.

By using 3D scanning, Grundfos has experienced several benefits and results across the organization.

In a development project with Siemens Gamesa, Zebicon has optimized the wind turbine manufacturer’s measurement process of stators and flanges.

Ammeraal Beltech Modular has invested in the fully automated ATOS ScanBox 4105, which is used for quality control of tools and parts.

HBN-Teknik has invested in the fully automatic ATOS ScanBox 5120, for running in new products and part verification.

The plastic company HN Group has invested in the fully automatic ATOS ScanBox 4105, for documentation and quality control.